What Does Thermal Imaging Mean?

This is a method that uses heat an object emits to locate or create a picture of a target item. The method is often referred to as thermal scanning, thermography, or infrared imaging.

The below image is of a Cummins diesel marine engine. It was taken while the engine was running during a sea trial. The image on the left is a conventional thermal image while the one on the right is a Thermal MSX® Image.

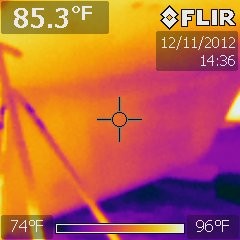

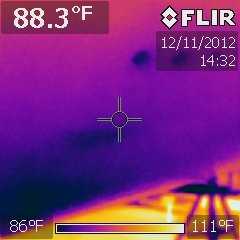

To the left is a hull thermal image and to the right is a Thermal MSX® Image.

As you can see in the above images, MSX® technology helps produce a sharper and cleaner thermal image. The clear and detailed images make it easy to locate problems.

What Makes Thermal Imaging So Important?

As you may already be aware, marine surveying is non-intrusive. The surveyor won’t disassemble objects to look inside if they suspect a problem. They only observe and listen, then write a survey report. With the help of thermal imaging, the surveyor can have more insight into a component. The use of thermography eliminates the need for disassembling components in order to check inside. In the past, you needed to hire a mechanic or expert to inspect inside a component during a marine survey. Today, our surveyor is able to look inside an alternator, electrical panels, power steering pump, and have a better knowledge of the state of a bearing, including whether there is excessive wear or misalignment. All this is done without dismantling components. This is all thanks to thermal imaging.

Thermal scans aid in identifying possible issues with a variety of parts, including bearings, manifolds, risers, and heat exchangers used in engine cooling systems. A surveyor can quickly locate coolant restriction in the engine using thermal imaging. Thermal imaging can also be used to identify potential issues that an electrician or marine technician might otherwise miss. This does not imply that we do not support working with qualified electrical and mechanical specialists. Their advice is priceless. We are only claiming that using thermal imagining improves our ability to perform our duties

How Thermal Imaging Works?

The greatest method for identifying temperature anomalies in industrial and electrical equipment is thermal imaging. Thermal imaging is effective on a range of materials, including wood, aluminum, steel, and fiberglass. This is because everything produces some degree of thermal radiation. The best thing is thermal cameras can operate in total darkness, unlike night vision, which requires some form of light. Thermography tools have been employed in a variety of industries to help with equipment maintenance and repair. Most often, thermal imaging is used to inspect the hulls and systems of commercial airplanes. The technology only recently started being used in marine surveying. At Sun Coast Marine Surveying and Consulting, we work hard to provide our surveyors with the best and latest tools so they can better serve our clients.

Thermographic cameras are similar to portable digital video cameras in appearance and operation. The exception is a thermal camera uses thermal imaging. We employ FLIR® brand infrared cameras in our business. Only FLIR® cameras with MSX® technology are used by our team. While only FLIR® cameras have the MSX® technology, not all FLIR® camera brands use this technology. The beauty of having the MSX® technology is that it adds key details. Moreover, thermal scanning is completed in real time and gives a thermal image that contains text, numbers, and even structural information. This facilitates the speedy identification of the object that was scanned.

Thermographic cameras are similar to portable digital video cameras in appearance and operation. The exception is a thermal camera uses thermal imaging. We employ FLIR® brand infrared cameras in our business. Only FLIR® cameras with MSX® technology are used by our team. While only FLIR® cameras have the MSX® technology, not all FLIR® camera brands use this technology. The beauty of having the MSX® technology is that it adds key details. Moreover, thermal scanning is completed in real time and gives a thermal image that contains text, numbers, and even structural information. This facilitates the speedy identification of the object that was scanned.

When a focus object emits infrared light, that light is focused to a special lens on the infrared camera. The MSX® technology includes an additional lens which creates digital images. This leads to the production of three distinct images of a target item.

1. Digital Image 2. Thermal Image 3. Thermal MSX

A thermal MSX® image is basically a combination of the three images; overlaid to form one image. This gives an image that is crisper and easy to identify.

So What Are the Benefits of Thermal Imaging?

Thermal imaging offers many benefits to various industries. In this section, we will be focusing solely on benefits to the marine surveying industry. Some of these advantages are:

- No contact is needed. The surveyor will never have to touch hot or moving engine room components thanks to thermal imaging. Additionally, the technique enables the inspection of electrical parts without the danger of electrocution.

- Everything takes place instantaneously. The scanning and recording by a thermal camera is instant. You don’t have to wait for an image to be generated. Everything happens in real life.

- Thermal patterns are visible. This is significant since it cuts down on the need for hiring a technician or mechanic for a boat inspection. As a customer, you’ll be able to save time and money. The surveyor, on the other hand, will cut down on the time it takes them to finish a survey. Thermographic representations make it simple to locate temperature abnormalities.

- Helps create a more comprehensive survey report. We provide thermal imaging without charging an additional fee at Sun Coast Marine Surveying and Consulting. We use it because it aids in our comprehension of many parts, including hulls, decks, engines, tanks, gearboxes, and electrical systems. By utilizing thermal imaging, we can locate faults, leaks, and delamination. We will present our conclusions in a detailed survey report.

How Will Thermal Imaging Make Your Boat Safer

With thermal imaging, you not only see the problems that are existing but also the ones that are inevitable. This crucial information makes it possible for you to fix these problems in time and thus make your investment a lot safer. It is possible to employ thermography to find unusual heat that could start an electrical fire. In order to avoid water damage or an explosion, thermography can also be used to detect water or gasoline leaks from the tanks. Thermal imaging can further be used to find temperature anomalies in the engine that could cost a lot of money and time to fix.

A thermography was used to find delamination in the image to the right. As you can see, thermal imaging helps surveyors identify potential structural faults that conventional survey techniques could miss.

Sun Coast Marine Surveying and Consulting continues to apply the tried-and-true conventional surveying methods together with new technologies. We still use conventional methods like percussion soundings and GRP33 moisture meter. Our reliance on FLIR® thermal cameras that employ the MSX® imaging technology not only distinguishes us from our rivals but also enables us to provide more than just standard surveys.

Thermal image of a onboard generator operating under a load.

Thermal image of a Cummins Diesel engine

Infrared thermal image of hull delamination on the lower right side of the image.

Infrared thermal image of a hull bottom with hidden delamination under the fiberglass